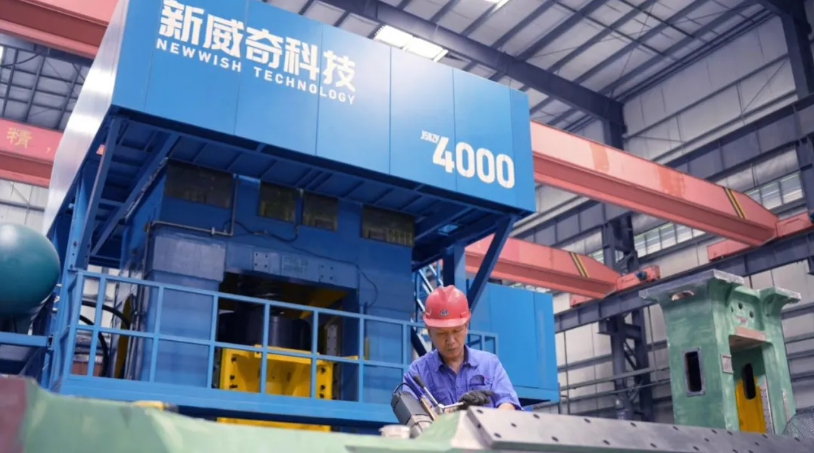

A few days ago, China's largest tonnage of 4000 tons servo direct drive electric screw press was successfully developed in Wuhan, experts said that this is a breakthrough in China's high-performance industrial machine. This advanced forging equipment developed by Wuhan Newwish Technology Co., Ltd (hereinafter referred to as: Newwish) is in service in China's aerospace industry and is used to produce key components of advanced aero engines.

Photo | Newish was founded in 1993 by Professor Huang Shuhuai, former President of Huazhong University of Science and Technology

According to Dr. Feng Yi, the "closed disciple" of Professor Huang Shuhuai, president of Huazhong University of Science and Technology, and the general manager of Newwish, the press nominal pressure is 4000 tons, long-term allowable load is 6400 tons, cold striking force is 8000 tons, the full energy of the moving part is 1000 kJ, and the application of multi-transmission frequency direct torque control technology. The use of self-customized development of large torque (peak 120000 nm) permanent magnet synchronous ring motor direct drive, zero transmission, no noise, maintenance-free, the design and performance indicators have reached or partially exceeded the foreign similar products, to reach the international advanced level, once again a new record of this type of domestic equipment.

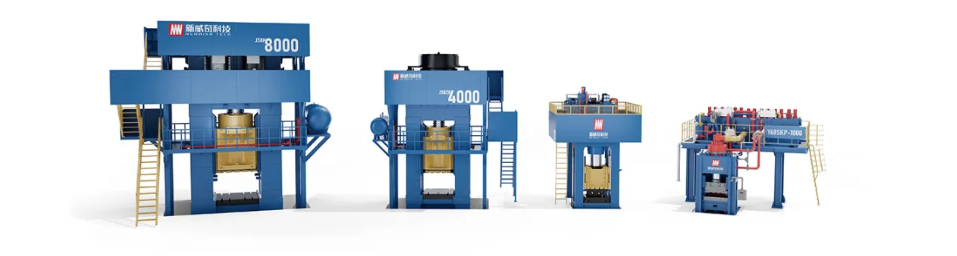

Photo | Figure | New VIC J58ZK-4000 servo direct drive electric screw press

Industrial machine is "the machine of manufacturing machines", forging equipment is one of the most important industrial machines, and advanced heavy forging equipment is a symbol of the strength of a country's high-end equipment manufacturing industry, the replacement of aerospace equipment, the rapid development of rail transit, the transformation and upgrading of the automotive industry, etc., all need advanced heavy forging equipment as industrial support.

Photo | Professor Huang Shuhuai (second from right) led a team to study forging technology abroad

In the early 1990s, a large number of foreign machine tools poured into the Chinese market, but in the core technology of foreign enterprises are to suppress and block the strategy. Professor Huang Shuhuai, who stepped down as president of Huazhong University of Science and Technology, founded New Weiqi, advocating independent innovation to solve the problem of "stuck neck". In 2003, Newwish successfully developed the first domestic electric screw press, filling the gap in China.

Figure | Professor Huang Shuhuai, founder of Newwish and former President of Huazhong University of Science and Technology, and the first electric screw press in China (first from left)

Subsequently, Newwish fully into the industrialization, continuing the development direction of "self-research, self-creation, self-manufacturing", in 2016, the first in the domestic development of J58ZK series servo direct drive electric screw press, a high-end forging equipment with zero transmission, high efficiency and precision, no movement noise and other advantages, and quickly won the favor of the market and customer recognition. In October 2023, the heavy-duty plant with a lifting capacity of 300 tons per piece broke ground, and the next step will be to develop the world's first 10,000-ton servo direct drive CNC electric screw press representing the highest international level.

Figure | Newwish die forging core forming equipment series products

So far, Newwish has delivered more than 1,800 forging equipment, built more than 140 automatic forging lines, and served more than 500 users. In total, it has won 2 national awards, 9 provincial and ministerial awards, been selected as one of the top ten scientific and technological progress of China's intelligent manufacturing, and won the title of national specialized and special new key small giant enterprise in 2021.