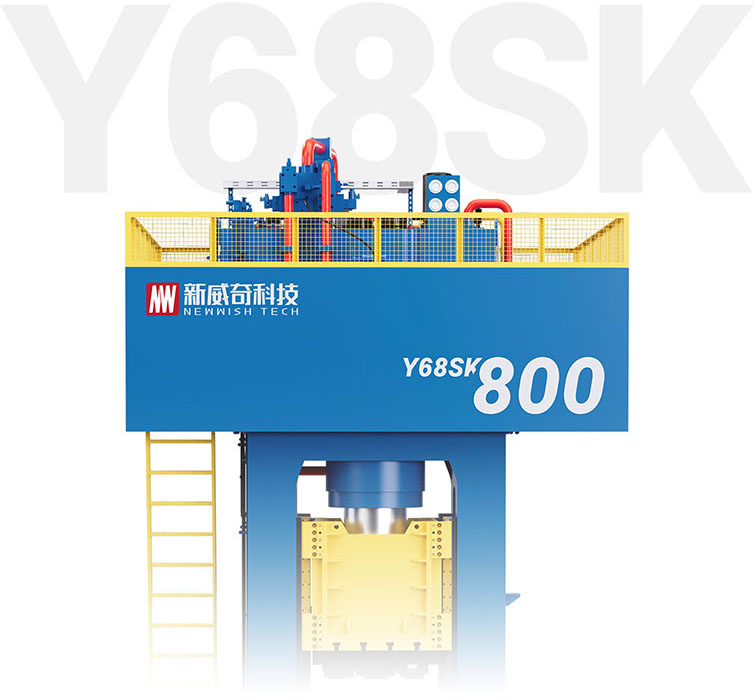

Employs a servo motor to drive the main hydraulic pump, minimizing control valve use and ensuring precise control of slider speed, pressure, and stroke. This energy-efficient hydraulic control allows customizable slider motion curves for various processes

Pump-controlled servo technology

Pump-controlled servo technology Hydraulic System

Hydraulic System Mechanical Structure

Mechanical Structure Lubrication System

Lubrication System

PLC Control Technology

PLC Control Technology

HMI Interaction Platform

HMI Interaction Platform