Aerospace

Turbine Discs, Turbine Blades, Compressor Blades, Wing Beams, Landing Gears, Bolts, etc.

Balancing the dual attributes of forging hammer and press machineSuitable for various forging processes and manufacturing materials, capable of forging almost all types of forgings

Suitable for various forging processesand manufacturing materials

Aerospace

Turbine Discs, Turbine Blades, Compressor Blades, Wing Beams, Landing Gears, Bolts, etc.

Auto Parts

Crankshafts, Connecting Rods, Wheel Hubs, Gears, Drive Shafts, Axles, Steering Knuckles, Control Arms, etc.

Construction

Excavators, Loaders, Bulldozers, Cranes, Rollers, Graders, Pile Drivers, etc.

Agricultural

Tractors, Cultivators, Seeders, Combine Harvesters, Sprayers, etc.

Mining

Crushers, Drills, Loaders, Hoists, Ball Mills, Conveyor Equipment, etc.

Shipbuilding

Propeller Blades, Drive Shafts, Bearing Seats, Rudder Pins, Anchor Chains, Keel Connectors, etc.

Rail Transit

Wheels, Axles, Chain Links, Brake Arms, Side Beams, Door Hinges, Couplers, etc.

Energy

Bearing Seats, Brake Discs, Yaw Shafts, Pitch Shafts, Rotor Shafts, Flanges, Bearings, etc.

Hardware

Hand Tools, Power Tools, Gardening Tools, Striking Tools, Measuring Tools, Machining Tools, etc.

Electric Power

Line Clamps, Insulator Clamps, Serial Connectors, Suspension Chains, Anchor Chains, Insulator Rings, etc.

Medical

Surgical Forceps, Scalpels, Bone Hammers, Artificial Joints, Bone Plates, Bone Screws, Stents, etc.

Others

Pump Components, Valve Components, Pipe Fittings, Drill Components, Window and Door Fittings, etc.

Alloy Steel

AISI 4130, AISI 4140, AISI 4340, AISI 8620, AISI 4145, AISI 4330, 10B38, AISI 6150, AISI 6170, AISI 8740, etc.

Aluminum Alloy

6061, 7075, 2024, 6063, 5052, 6082, 2014, 7005, 7020, 7050, 5083, 5086, 5182, 6101, 6201, 6351, etc.

Titanium Alloy

Ti-6Al-4V, Ti-3Al-2.5V, Ti-5Al-2.5Sn, Ti-8Al-1Mo-1V, Ti-10V-2Fe-3Al, Ti-4.5Al-3V-2Fe, Ti-6Al-2Sn-4Zr, etc.

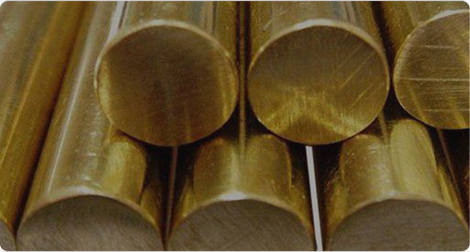

Copper Alloy

C5191, C5210, C54400, C63000, C71500, C70600, C77010, C75210, C28000, C26000, C46400, etc.

Stainless Steel

304, 304L, 316, 316L, 410, 420, 440C, 430, 446, 201, 202, 301, 309, 310S, 2205, 2507, 17-4 PH, 15-5 PH, etc.

Superalloys

Inconel 718, Inconel 625, Rene 41, Haynes 188, Stellite 31, A-286, Waspaloy, Ti-6Al-2Sn-4Zr-6Mo, etc.

Adopting the advanced global drive technologies significantly double the core advantages of electric screw presses

Advanced driving solutions doublethe core advantages of electric screw presses

Permanent Magnet Synchronous Servo

Permanent Magnet Synchronous ServoThe J58ZK uses a low-speed, high-torque permanent magnet synchronous motor, offering excellent torque density and performance. Its full closed-loop programming control ensures outstanding flexibility and precision.

Direct Drive, Silent, Durable

Direct Drive, Silent, DurableBy integrating the motor rotor and flywheel, the system achieves zero energy loss and transmission, greatly improving production efficiency. The streamlined design enhances reliability by minimizing fault factors.

Long slide, Long guide rail

Long slide, Long guide railEnhanced guide accuracy and overload resistance, designed to meet multi-station forging requirements.

Braking System

Braking SystemNew braking design with high braking torque and short response time, ensuring safety and reliability.

Protection System

Protection SystemIncludes overload protection, cooling circulation, thin oil lubrication, and grease lubrication.

Self-developed specialized CNC system with open design offers high automation, simple use, full features, easily upgradable to a full automation line

PLC Control Technology

PLC Control TechnologyUtilizing a programmable logic controller as the core, supplemented by analog and digital expansion modules, along with inverter speed and torque control, and motor angle and slider displacement detection circuits, achieving precise control of energy and slider position

HMI Interaction Platform

HMI Interaction PlatformThe latest HMI interactive platform with touch screen and intuitive UI monitors the status of the equipment in real time, including key parameters like displacement and energy. Fault warning and intelligent maintenance functions to ease maintenance workload

Adoption of advanced inspection technology, construction of refined quality management system

Adoption of advanced inspection technology, construction of refined quality management system

Mitigates adverse effects from human operation, material, and tool ,independently assessing equipment impact on quality. Accurately measures and optimizes machine performance to meet production requirements

Conducts multi-dimensional analysis and evaluation of mechanical components, including stress, deformation, displacement, strength, fatigue, vibration, modal analysis, thermal load, thermal expansion, and structural integrity

Utilizes ultrasonic (UT), magnetic particle (MT), and penetrant testing (PT) for nondestructive inspection, identifying internal and surface defects like cracks, porosity, inclusions, weld penetration, and slag

Material Tests

Process Control

Factory Inspection

| Models |

|---|

| Nominal Force[kN] |

| Continuously Permitted Press[kN] |

| Gross Working Capacity[kJ] |

| Max. Slide Stroke[mm] |

| Max. Stroking Rate[min⁻¹] |

| Backing Plate Thickness[mm] |

| Min. Enclosed Height[mm] |

| Screw Diameter[mm] |

| Area of Table F - B[mm] |

| Area of Table L - R[mm] |

| Area of Slide F - B[mm] |

| Area of Slide L - R[mm] |

| Installed Power[kW] |

| Average Power[kW] |

Equipment selection options and customized services enhance the automation, informatization, and intellectualization levels of production line

Empowering Automation, Informatization, Intellectualizationproducts and technologies for forging lines