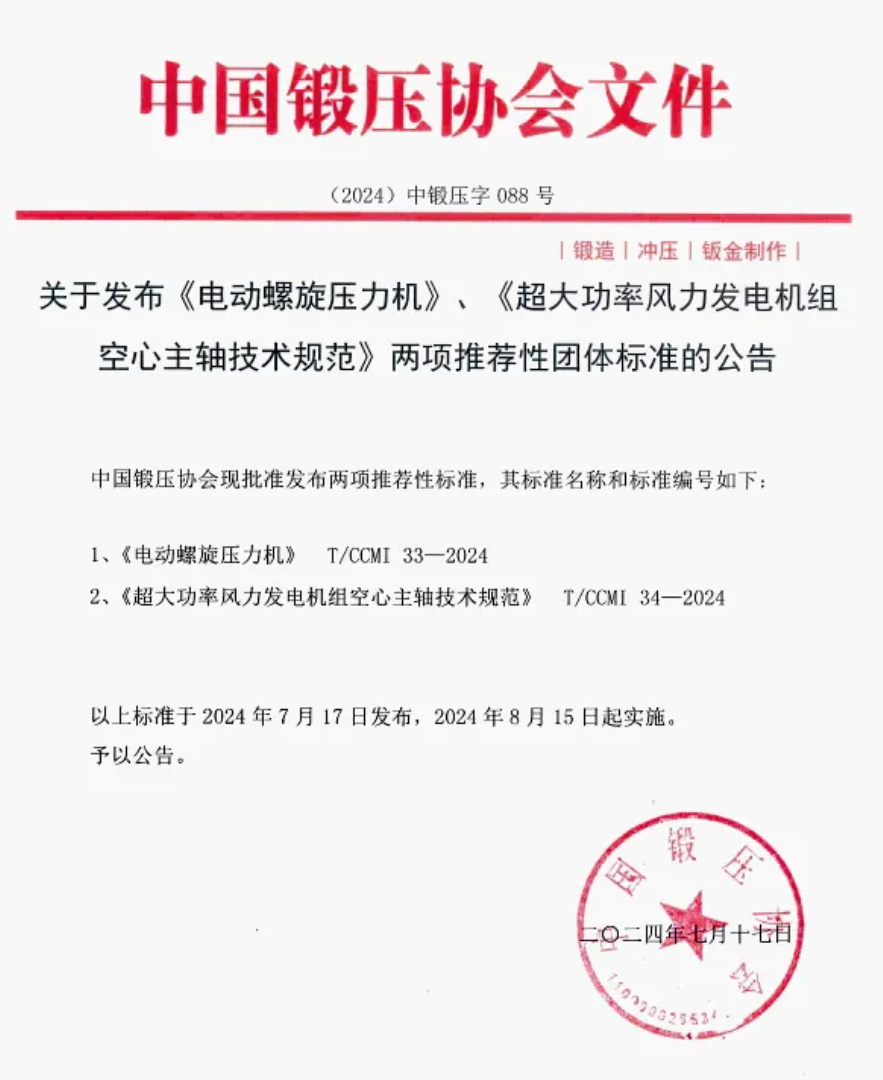

On July 17, Wuhan Newwish Technology Co., Ltd. and China Forging Association issued the "Electric Screw Press" group standard (number :T/CCMI 33-2024), which will be officially implemented on August 15.

Click to download: "Electric Screw Press" Group standard

TCCMI 33-2024Group standard for electric screw presses.pdf

Main drafting unit

Wuhan Newwish Technology Co., LTD

Huazhong University of Science and Technology, Hubei tri-Tri-ring Forging Co., LTD

…

Principal draftsman

Feng Yi, Yu Jun, Xiong Youbin, Zhang Kai

Deng Lei, Jin Junsong, Zhou Ming, Zeng Jun

…

Applicable to nominal force 1600kN~160000kN specifications

Electric screw press

With the continuous expansion of the application range of electric screw presses, the existing industry standards have been unable to meet the actual needs of production equipment enterprises and user enterprises.

March 2024 "Electric Screw Press" group standards seminar

In order to meet the development needs of industry technology, in 2022, as the leading unit, under the initiative of the China Forging Association, Newwish has united a number of industry enterprises, user units, research institutes and well-known universities, etc., after many discussions and demonstrations, and widely solicit opinions. It took two years to successfully develop China's first "Electric Screw Press" group standard.

May 2024 "Electric Screw Press" group standard expert review meeting

The "Electric Screw Press" group standard published this time defines the industry terms and definitions in detail, describes the classification, structure and basic parameters of the equipment, and adds the number of strokes, effective energy tests, temperature rise limits and other related technical indicators. In addition, the standard provides clear guidance for practical operations such as marking, packaging, transportation and storage.

In the field of electric screw press has more than 20 years of research and development, manufacturing and management experience, in the formulation of this standard, for quality management, service life, environmental protection and safety and other aspects put forward strict requirements, for the implementation of the standard, reference and standardization provides a solid technical support and rich experience guarantee.

Newwish always adhere to continuous improvement, the pursuit of excellent quality policy, strict control of material entry, process control, factory inspection, the use of finite element analysis, flaw detection, work ability index and other advanced testing means, for each equipment to carry out more than 40 structural components of the full-size testing, more than 30 installation process traceability testing, more than 20 key performance indicators delivery testing. Identify key control nodes and build a refined quality management system.

The implementation of the standard will effectively promote the technological development of China's electric screw press, accelerate the replacement of high-end intelligent equipment, enhance the international competitiveness of China's aviation, aerospace, automotive and other key areas, and promote the high-quality development of manufacturing.