Issues

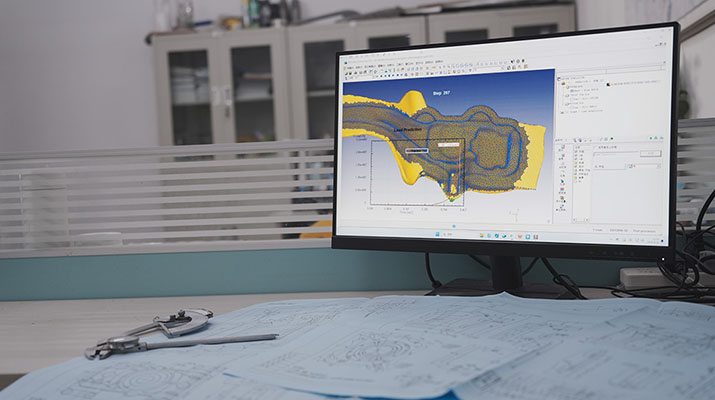

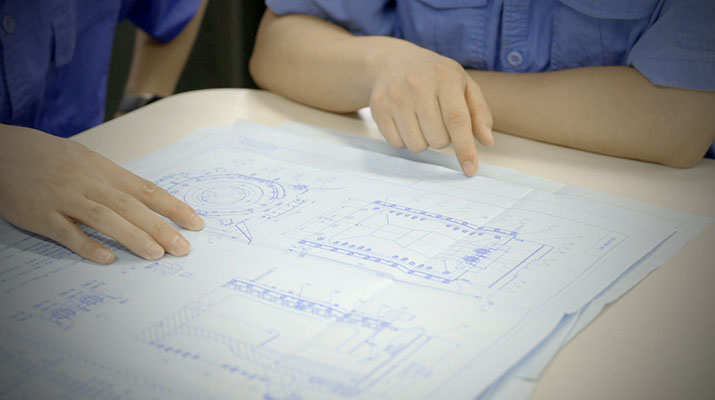

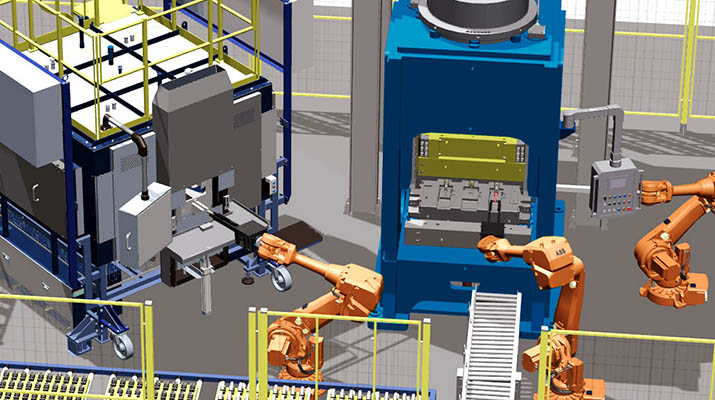

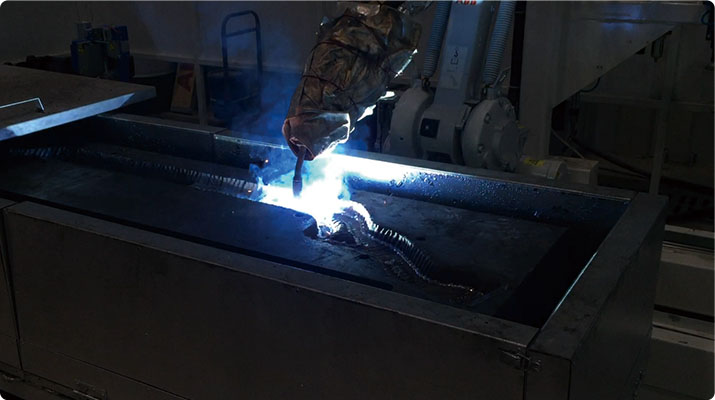

Common challenges encompass process complexity, parameter optimization, precision and durability in mold design, cost control and economy, equipment compatibility and process adaptability, plus production line flexibility and scalability. Tackling these requires interdisciplinary expertise