The J58ZK-4000 servo direct drive CNC electric screw press independently developed by Newwish successfully rolled off the assembly line, and successfully completed the test and acceptance (nominal pressure 40000kN, long-term allowable load 64000kN, cold strike force 80000kN, the total energy of the moving part 1000kJ). The design and performance indicators have reached or partially exceeded the similar foreign products, reached the international advanced level, and once again refreshed the new record of this type of domestic equipment.

The electric screw press is well recognized by the industry because of its high efficiency and energy saving, strong versatility and wide process application, and is widely used at home and abroad. However, in China's aerospace, national defense and other key sensitive areas required for high-performance direct drive CNC electric screw presses have long relied on imports.

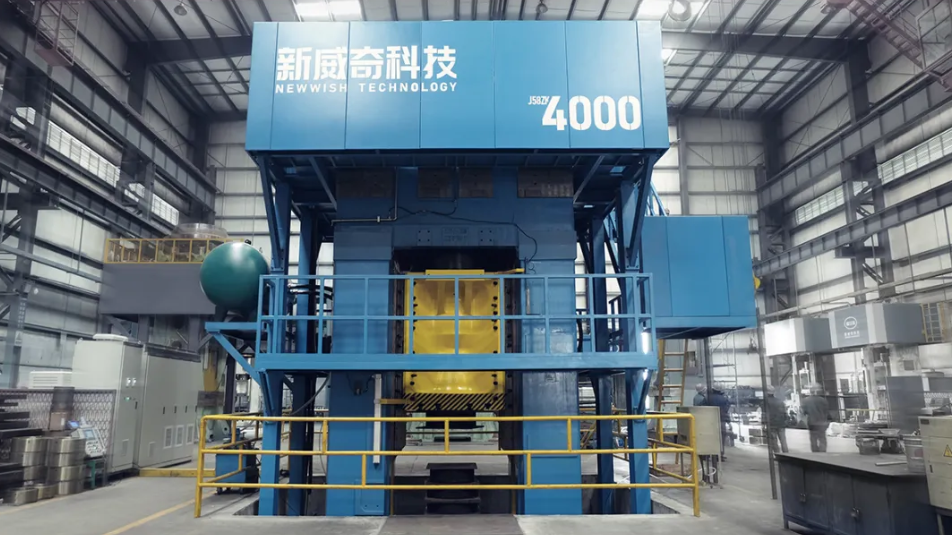

Figure J58ZK-4000 servo direct drive CNC electric screw press

This time, the J58ZK-4000 fills the gap in the field of the same type of products in China once again, further promotes the technological innovation of industrial mother-machine.

Video J58ZK-4000 servo direct drive CNC electric screw press

The J58ZK-4000 model uses ABB multi-transmission frequency conversion direct drive DTC technology, and adopts self-customized and developed large torque (peak 120000NM) permanent magnet synchronous ring motor directly driven, zero transmission, no noise, maintenance-free; Matching the independent research and development of the special CNC system, the forging process in the strike energy, deformation rate and slider position to achieve accurate control, can better achieve high precision, efficient and stable production of forging products. It is also especially suitable for precision forging of non-ferrous metals such as titanium, aluminum and magnesium.

High precision

1. The striking energy can be accurately controlled to effectively improve the forming accuracy;

2. Long guide mechanism design, accurate guide, faster response;

3. High strength cast steel split prestressed fuselage to ensure forming stability.

High efficiency

1. The motor direct drive flywheel does work, and the transmission efficiency is significantly improved;

2. Precise control can reduce mold load and improve mold life;

3. With better acceleration performance, greatly improve production efficiency.

Safe and reliable

1. Combined flywheel design, overload safety protection;

2. New brake design, braking speed response;

3. The material of the main components is higher than the industry standard.

Energy saving and environmental protection

1. Direct motor drive, more efficient, more energy saving;

2. No transmission noise, improve the working environment;

3. Simple structure, strong durability, maintenance free.