The pre-forming production line of precision forged blade independently developed by Newwish has been successfully completed and successfully passed the pre-acceptance of a military central enterprise. The project takes Y68SKP-1000 CNC servo hydraulic horizontal forging machine, which is the largest tonnage in China, as the core host equipment, and integrates fully automated overall solutions such as loading and unloading, heating, mold base, spraying lubrication, robot handling, and data acquisition. In the future, it will serve in China's aerospace industry and be used to produce key components for advanced aircraft engines.

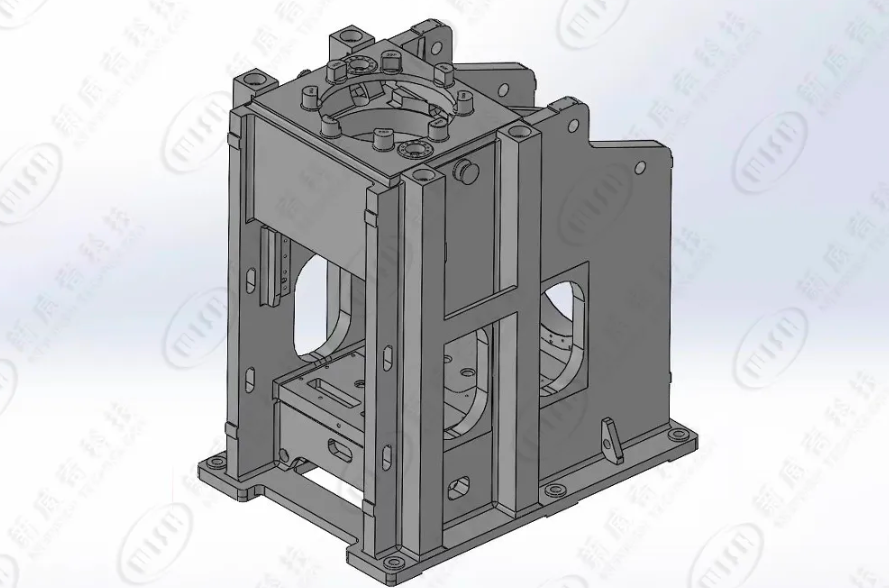

Figure Y68SKP-1000 CNC servo hydraulic horizontal forging machine

The Y68SKP series CNC servo hydraulic horizontal forging machine independently developed by Newwish can gather material at any part, and can achieve parts extrusion rod, heading, bending, forming and other functions, especially suitable for the combination of vertical forging and horizontal forging precision forging of complex parts. Suitable for black metal and non-ferrous metal forgings in cold forging, warm forging, hot forging, die forging and precision forging forming, such as titanium/stainless steel/superalloy blade, semi-shaft forging compared with the traditional mechanical flat forging machine, not only has the major advantages of full stroke work, and can greatly improve the forming accuracy and production efficiency. At the same time, it has the outstanding characteristics of energy saving and environmental protection, simple maintenance and high degree of automation.

Figure precision forging blade preforming process diagram

Y68SKPseries

CNC servo hydraulic horizontal forging machine

The working pressure and speed of each direction drive unit are controllable and adjustable

High strength fuselage to ensure forming accuracy and consistency

The control system has high configuration and rich interfaces for easy automatic integration

Drive part - servo hydraulic system/servo pump control system

The vertical clamping cylinder is driven by permanent magnet synchronous motor, and the horizontal top forging cylinder is driven by servo pump control system. Faster response, higher efficiency and lower energy consumption than similar products.

Mechanical part - Finite element analysis/High strength integral welded fuselage

Through finite element analysis and optimization design, the fuselage has high strength and good rigidity. The slider has high guiding accuracy and strong anti-biased load ability, which greatly improves the forming accuracy and consistency of the product.

Control part - Siemens PLC + S120 system

Key parameters such as slider position, pressure value and speed can be accurately preset. Provide friendly man-machine interaction experience, simple operation, easy maintenance. Extensive interface, easy to automate integration.