Project Equipment

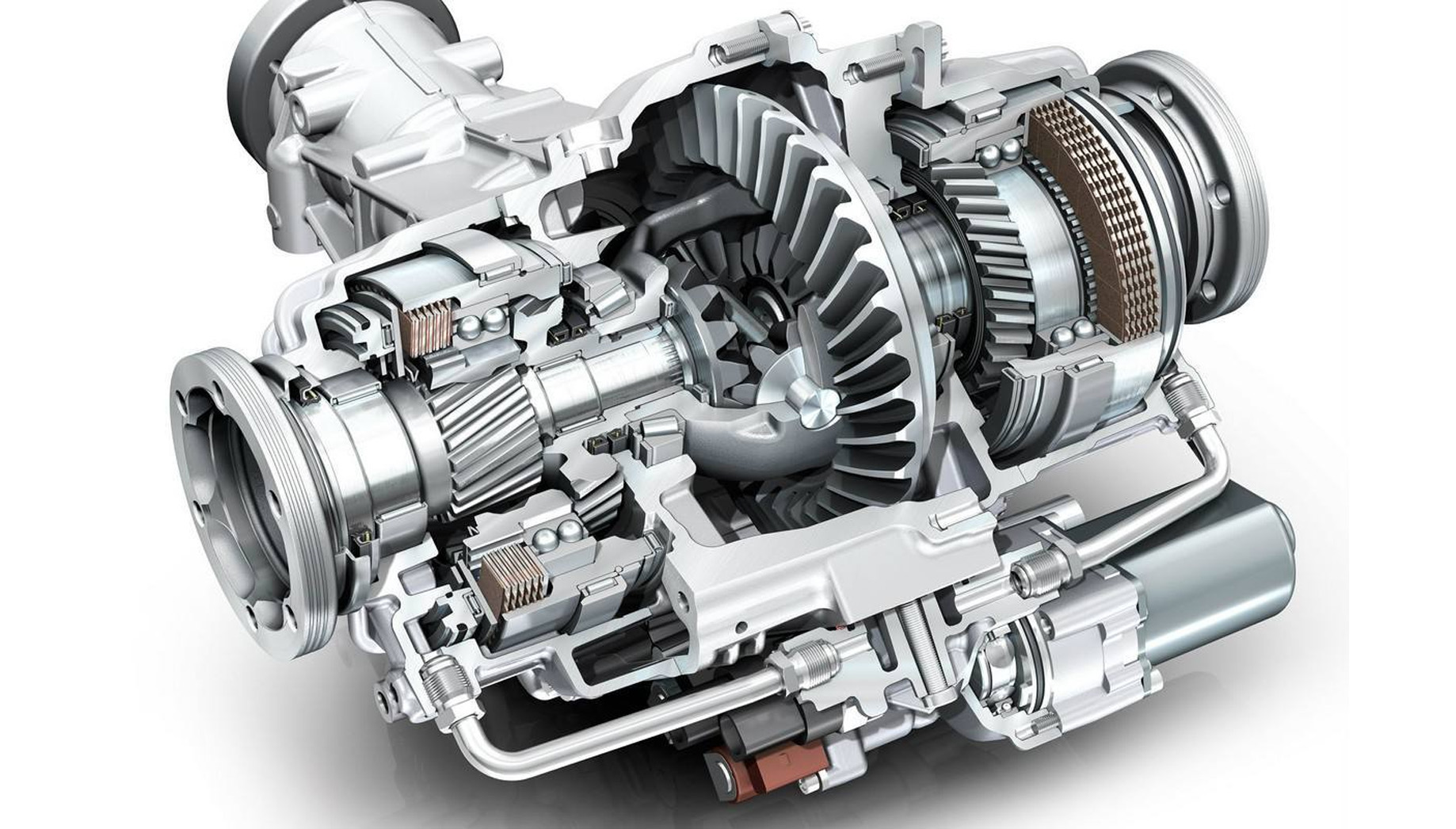

At present, the total weight of precision forgings used in an ordinary car in the world has reached (40-45) kg, of which the total weight of gear parts is more than 10 kg. The weight of a single precision forged gear can reach more than 1 kg, and the tooth accuracy reaches (DIN) 7 level. With the requirements for lightweight cars and the increase in people's environmental awareness, the automotive gear manufacturing industry will use more precision forging technology

Automobile

Industry

Half Axle Gears

Forgings

Low Alloy Steel

Material

Automatic

Mode

800℃-1350℃

Temperature Range

≥60s/item

Lead Time

Aerospace parts need to operate under extreme conditions such as high temperature, high pressure, high stress, etc., which has very high requirements on the materials and processing technology of die forging products

Die forging products are vital for auto powertrain, suspension, and steering, and crucial for boosting motorcycle strength and lightness

Die forging products are widely used in the civil engineering, mining and agricultural machinery industries

They are used in a wide range of applications due to their excellent performance and lightweight characteristics